Molecular biology has led to the most important discovery of biotechnology: it is today it is possible to separate the gene responsible for coding the production of certain substances, to transfer it to another host organism and thus to produce certain useful proteins more efficiently. Thanks to these advances, biotechnology today produces large-scale hormones, vaccines, blood clotting factors and enzymes.

Furthermore, biotechnological production of proteins avoids the disadvantages production from higher organisms:

1. Unlike the culture of microorganisms, the culture of cells of organisms greater than large scale is not practical because their growth is slow and their contamination is frequent.

2. The cost of a cell culture is much higher than that of a microbial culture.

3. The source of cells of higher organisms is much more limited than that of organisms unicellular, which, another advantage, reproduces easily and quickly.

This field of biotechnology therefore makes it possible to produce new proteins, for example enzymes that will be used as biocatalysts. The specific capacity of biocatalysts is governed by molecular structure; using the recombinant DNA technique, it’s possible to selectively modify genes that encode cell synthesis of enzymes. Subsequently, when transferring the new DNA into a host icroorganism, one can obtain a new strain that will produce the desired enzyme.

Plants and plant tissue culture

Plants, in addition to their key role in food production, are an important source of raw materials and medicines. Indeed, remember that 25% of current drugs

are of plant origin.

On the other hand, the cultivation of single-celled plant organisms for the production of biomass or the extraction of high value-added products is a practice that is increasing day by day, as molecular biology develops.

Finally, the reproduction of modified plants, via replication techniques, has already been successfully tested.

This technology makes it possible to remedy deficiencies, to improve species and to develop resistance to the plagues and diseases of many plant species.

Culture of mammalian cells

The first study on the spontaneous fusion of two different somatic cells to form a heterokaryote (a minimum of two nuclei and a single cytoplasm) was published in 1960 by Barsky and his French collaborators. However, we had already observed at that time the appearance of polynuclear cells in tissue cultures of mammals infected with certain inactivated viruses.

Heterokaryotes provide the expression of genes for the two parental cells. In

1975, Kohler and Milstein applied this property to their famous synthesis of monoclonal antibodies, obtained by the fusion of antibody-producing lymphocytes with malignant cells myeloma, which have the property of rapid reproduction. These hybrid myeloma cells retain this property (rapid reproduction) while expressing specific antibodies.

Some proteins are produced only from cultures of mammalian cells, this large-scale cell culture is one of the goals of molecular biologists. Monoclonal antibodies and interferon are two examples of this type of protein, which are very important for the preparation of therapeutic and analytical products.

Biocatalysts

Enzymes are natural catalysts; as is the case with all natural processes, they are very specific and demonstrate thermodynamic efficiency. Used for centuries, especially in the food production sector, they are one of the most of biotechnology.

The use of enzymes (isolated or in dead or dying cells) is of great importance not only in the food industry but also in the production of substances chemicals, analytical and diagnostic systems, disease treatment, and the emerging cleaner technology industry.

The use of enzymes in all these areas has been made possible thanks to better knowledge of the function of enzymes in the metabolic systems of living beings,

structure of enzymes and above all thanks to the possibility of obtaining synthetic enzymes through genetic manipulation of microorganisms. These factors have resulted in many companies specialize in the large-scale production of enzymes of microbial origin.

Enzymes are becoming more and more important in sustainable industrial development. They have have already been used in the development of industrial processes in order to obtain products without waste or containing a minimum of biodegradable waste. Manufacturing companies should in the near future pay great attention to the compatibility of waste as well as recycling used water and enzymes can solve many of these problems.

Indeed, they can replace toxic or corrosive chemicals in some processes. In addition, their advantage is that they can be used, deactivated and decomposed

in simpler, fully biodegradable products. Many industrial processes work at high temperature or pressure or under highly acidic or basic conditions. Enzymes can avoid these extreme conditions as well than corrosive reagents. They work at moderate temperatures, at atmospheric pressure and in solutions close to neutral pH. These are highly specific catalysts that give purer products with less side reactions.

Consequently, any process replacing chemicals with enzymes is a process less polluting, more environmentally friendly and less expensive. We now offer you a quick list of the enzymatic processes currently used in many sectors in order to reduce the chemical load by eliminating the industrial production of aggressive and toxic or simply polluting substances.

Detergent industry :

- enzymatic degradation of proteins, starch and fat stains in washing clothes,

- use of lipolytic enzymes in substances for dishwashers,

- use of enzymes as surfactants.

Textile industry :

- stone washing of jean type fabrics,

- enzymatic desizing of flat woven cotton fabric,

- ecological bleaching,

- enzymatic scouring of cotton fabrics,

- degumming of silk.

Starch industry:

Enzymatic production of dextrose, fructose and special syrups for pastry, confectionery and the refreshment industries.

Beer industry:

Enzymatic degradation of starch, proteins and glucans made from the cereal blend used to make beer.

Pastry and bread-making industry:

Enzymatic modification of carbohydrates and cereal proteins in order to improve the properties of bread.

Wine and fruit juice industry:

Enzymatic degradation of fruit pectin in the production of fruit juices and wines.

Alcohol industry:

Degradation of the starch in sugars before the fermentation of the latter and the production of alcohol.

Food and additives industry:

- improvement of the nutritional and functional properties of animal and vegetable proteins

- conversion of lactose from milk and whey into sweeter and more easily digestible sugars,

- production of cheese aromas.

Animal feed industry:

Enzymatic hydrolysis of protein material from slaughterhouses to obtain flour with high nutritional value intended for animal feed.

Cosmetics industry:

Biotechnological production of collagen and other products for application to beauty creams.

Paper industry:

- enzymatic dissolution of the pitches,

- ecological bleaching of paper pulp,

- enzymatic control of the viscosity of starch coatings.

Tanning industry:

Skin preparation and removal of hair and grease.

Oils and fats industry:

Enzymatic hydrolysis of fats and lecithin and synthesis of esters.

Fine chemicals industry:

Synthesis of organic substances.

Bioremediation

Recall that bioremediation is the application of biotechnology to the treatment and reuse of waste products. Let’s take a look at some applications in this area.

Biological purifiers are a good example of simple applied biotechnology. It’s in

this case of a fixed bed of microorganisms which degrades the residual organic products up to obtain acceptable levels in waters that must be discharged directly. Sludge of these scrubbers are used as biomass for animal feed. There is also biotechnological processes for treating urban solid waste using aerobic or anaerobic fermentation to obtain biogas.

Another example of this technique, the tests of treatment of specific problems using of biotechnology: let us cite digestion, via microorganisms, of floating oil slicks on the sea after an oil tanker accident resulting in a spill. Also in this area, microbial degradation studies of cellulose waste are carried out in order to obtain biomass (single-cell proteins).

It has been estimated that the amount of protein likely to be obtained from agricultural waste in this way would be sufficient to feed the entire world population. Finally, note the presence of other studies in progress: the application of biotechnology for the detoxification of polluted soils. This technique uses higher plant cultures that fix heavy metals and remove organic pollutants.

Fermentation

With biocatalysis, fermentation processes are the oldest forms of biotechnology. Fermentation is the application of microbial metabolism to transform matter into value-added products. This process is able to produce an incredible variety of useful substances, for example citric acid, antibiotics, biopolymers, unicellular proteins, etc.

The potential is immense and very vast, it is enough simply to know the adapted microorganism, to control its metabolism and its growth and to be able to use it on a large scale.

The enzymes business

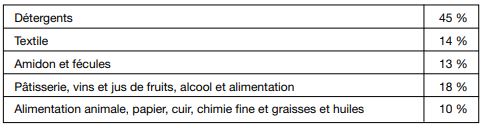

It is estimated today that the world market for enzymes is approximately 1.108 billion euros. Depending on the industrial application of enzymes, this market is divided in the following way:

The most widely used enzymes are proteases, amylases and cellulases. Even though enzymes are widely used in industry, they represent only a small amount of the total of the chemicals market. This is due to the following reasons:

• The absence, in many industrial sectors, of sufficient enzymological knowledge.

• Refusal to incorporate enzymes into traditional manufacturing processes due to

compulsory investment in new machinery and materials.

• The obstacle represented by the change of attitude in certain sectors.

• Finding the right enzymes for each process is very important, the need for filtering prior enzymatic.

Fuels and organic products as an alternative to petroleum

Petroleum is a non-renewable raw material, which means that its uncontrolled use or ascending is limited. As biotechnology uses renewable materials, its controlled use can extend endlessly. In the event of oil depletion, biotechnology can therefore provide two solutions: on the one hand, new fuels and, on the other hand, an alternative source of organic products. The use of cane sugar manufacturing waste for getting alcohol is an example of a process that saves energy.

Methane, from the fermentation of agricultural waste (biogas), is another fuel

potential from biotechnology. This is a biotechnology easily adaptable to

agricultural societies with few resources. The most sophisticated and perhaps the most sought after biotech fuel is hydrogen derived from the biophotolysis of water. This technology is based on the association of the photosynthetic capacity of chlorophyll in plant cells and the hydrogenase activity of a bacterial enzyme.

The great advantages of this water-derived fuel is that it does not produce pollution when it burns and its original reagent regenerates. Unfortunately,

this technique is still under study.

Biotechnological process engineering

The application of chemical engineering techniques to biotechnology processes has led to the emergence of the science of bioreactors, a technical area linked to both chemical engineering and biology, microbiology and biochemistry and which includes the study and design of reactors fixed bed, pH and temperature control probes, reagent and aeration dosing pumps, the design of agitators, the study of different methods of immobilization of enzymes and microorganisms and the design of various filters. All of these techniques have today a name, process engineering. All this biotechnological knowledge must move to a production level that will transform them into profitable elements.

This mostly requires scaling processes and technologies from the engineering sector, which have to adapt to the specific properties of living biotechnology organisms. here is some examples of processes: collection, pre-treatment and filtration of raw materials, reactor design, recovery and reuse of biocatalysts, extraction and product analysis, effluent treatment and water recycling.